VDO Tachometers

Vintage VDO Tachometers of the 70s

Some Volvo cars of the early 70s came with British Smiths Tachometers and others came with optional tachometers made by VDO of Germany. AccuTach has had the opportunity to reverse engineer these tachometers and to develop tools and information for people with vintage VDO tachometers.

Services

As vintage tachometers age, their permanent magnets weaken and the components age, so none of the original tachometers are accurate unless they have been recently recalibrated.If your vintage car's electronic tachometer has not been calibrated recently, the chances are the aging components inside have caused the tachometer to fall out of calibration or to fail completely. AccuTach Co. can repair and calibrate most vintage Smiths & VDO electronic tachometers.

AccuTach Co. does not repair or calibrate mechanical tachometers or speedometers.

Contact us to discuss the service you need.

Products

Calibration Tools

If you are interested in purchasing a calibration tool that will empower you to debug and calibrate electronic tachometers and speedometers of a number of styles, click here.

TechnoVersions TachMatch

TechnoVersions sells a device that can allow your stock VDO tachometer to work in cars with engine swaps or cars with modern ignition systems. We do not sell this product, but we do refer you to TechnoVersions if you need such a product. Check it out here: TechnoVersions TachMatch

Tach Background Information

Vintage VDO Tachometer Background Information

The VDO tachometers of the early 70s used a D'Asonval style ammeter as the needle movement. They consist of an electromagnet winding energized against permanent magnets to move their needles, which are set in jewel bearings. I never lubricate the jewel bearings because I have seen too many of them get gunked up resulting in binding movements. The tachometers are driven by a high voltage pulse from the ignition.

As these tachometers age, their permanent magnets weaken and the components age, so none of the original tachometers are accurate unless they have been recently re-calibrated.

Details of the Early 70s VDO Tachometers

Volvo Master Technician Roger Patricio of RP-R Sports bought a Smiths Tachometer Calibrator from AccuTach Co. to diagnose and calibrate his tachometers. The Smiths Tachometer Calibrator generates an accurate high current signal used to drive inductively coupled Smiths tachometers. It also has a square wave voltage output that can also be used to calibrate directly coupled tachometers such as the third generation Smiths tachometers and other tachometers with up to 12V inputs.

He contacted me because he was unable to get his VDO tachometers to work with the AccuTach Co. calibrator. We arranged for him to send me a 2” tachometer (left) and a 3” tachometer (right) for me to dismantle and reverse engineer:

2" VDO Tachometer

3" VDO Tachometer

I was also unable to get my calibrator to work with these tachometers, so I dismantled the 3” tachometer. I un-crimped and removed the front bezel and glass, removed the 4 screws on the back of the case (left) and then removed the press-fit needle and the tachometer face (right). This allowed me to develop schematics of the circuit.

3" Case, Rear View

3" PCB

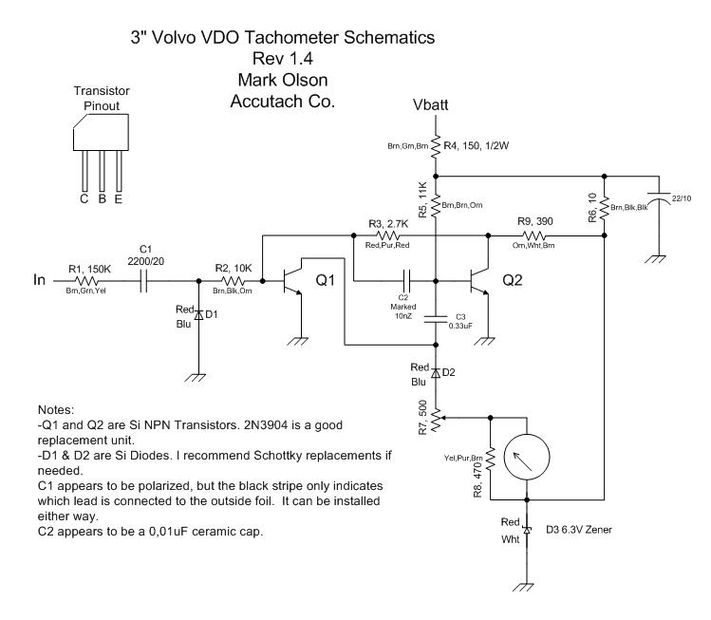

3" VDO Tachometer Schematics

The circuit consists of a 6.3V regulated Zener diode power supply that powers the D’Arsonval meter movement and a one-shot that drives current thought the meter for a fixed pulse width whenever there is an ignition event. The more frequent the ignition events the higher the duty cycle is of the current running through the meter leading to more needle deflection. The tachometer is calibrated by increasing or decreasing the one-shot on current thought the meter.

Current is not driven through the meter when transistor Q1 is off and it is driven through the meter when Q1 is on. When there is no voltage on the tachometer input, Q1 is off, and R4 & R5 pull up the base of Q2, turning it on. That drives Q2’s collector low which also keeps Q1 turned off via the feedback path. When Q1 is off, its collector is at 6.3V so no current flows through the meter.

When the voltage at the tachometer input rises enough to flow enough current into Q1 to turn it on, the collector slams close to 0V. C3 slams the base of Q2 well below 0V, turning Q2 off. This allows the collector to go a touch under 6.3V, which feeds back to the base of Q1 keeping it on, drawing current through the meter. R4 & R5 slowly charge C3, allowing the voltage on the base of Q2 to rise until it turns Q2 back on. That slams the collector close to 0V which is fed back to the base of Q1, turning it off. The combination of R4, R5 and C3 create the time constant that sets the one-shot pulse width. D2 keeps current from flowing back into the meter the wrong way.

The 3” tachometer I received actually had a bad Q2 in it that kept all 3 of its pins at 0V. I used a diode tester to learn that the PNP transistors had a Vbe of 0.7V, which means that the transistors are silicon transistors, not germanium. I calculated that the max current though Q2 is about 75mA and that it would be less for Q1. So I replaced Q2 with a 2N3904 and the one-shot started working again. So we know that a 2N3904 is a good replacement for dead transistors. I also validated that D1 & D2 are silicon diodes. I put the face and needle back on to the works. I calibrated the tachometer so that the RPM points were all off by the same amount and then rotated the needle on the shaft until it was accurate.

Assuming the stock, unknown transistor has similar switching characteristics to a 2N3904, the input circuit needs to provide about 1mA into the base of Q1 to fire the one-shot.

The input circuit consists of a 150K Ohm resistor R1 connected to AC coupling cap C1 connected to a 10K Ohm base current limiting resistor R2 connected to the base of Q1. D1 protects the base of Q1 from going negative, which would hurt Q1.

When the input voltage pulses high, C1 initially looks like a short circuit until it starts to charge, so the current going into the base is determined by the input voltage across R1 & R2, a total of 160K Ohms. Using Ohm’s Law, we see that, in order to get the 1mA base current we need to turn Q1 on, we need a voltage of 160K * 0.001 = 160V. This is why my calibrator, limited to about 12v, will not trigger the tachometer from the input.

R1 is way too large to allow the calibrator to work, but if the calibrator is attached to the input of C1, bypassing R1, then the calibrator will drive enough current to turn Q1 on. Unfortunately, that means that you must remove the tachometer from its case to check the calibration, but at least you can calibrate it if you need to. We sell an amplifier accessory for our Calibrator if you want to calibrate your vintage VDO tachometer in its case. Please see our Calibrator Products page for details.

If you want to convert this tachometer to work with modern low-voltage tachometer signals, simply solder a jumper across R1. Never do that for a high voltage points/condenser system, but it will work fine with low (5-12V) tachometer signal systems. I would recommend that you make a note on the case if you make such a conversion for future reference.

All this led me to wonder how the tachometer input could get such high input voltages, I thought about inductive loads (coils) causing voltage spikes when they are switched off, and that is what actually happens. A quick internet search led me to https://www.picoauto.com/library/automotive-guided-tests/primary-voltage/. Figure 5 and its corresponding paragraph give a good explanation of the phenomenon:

“The vertical line at the centre of the trace, called the 'induced voltage', is above 200 volts. The induced voltage is produced by a process called magnetic induction. At the point of ignition, the coil's earth circuit is removed and the magnetic field or flux collapses across the coil's windings. This in turn induces an average voltage between 150 to 350 volts (Figure 5). The coil's High Tension (HT) output is proportional to the induced voltage. The height of the induced voltage is sometimes referred to as the primary peak volts.”

Typical Ignition Waveform

It is interesting to note that in addition to my calibrator not being able to drive the tachometer at its input lug, neither can other low voltage tachometer signals such as those coming from electronic ignition units or EFI systems. If you want to adapt one of these VDO tachometers to work with those systems, you can simply solder a wire across R1, shorting it out. Never do that for a high voltage points/condenser system, but it will work fine with low (5-12V) tachometer signal systems. I would recommend that you make a note on the case if you make such a conversion for future reference.

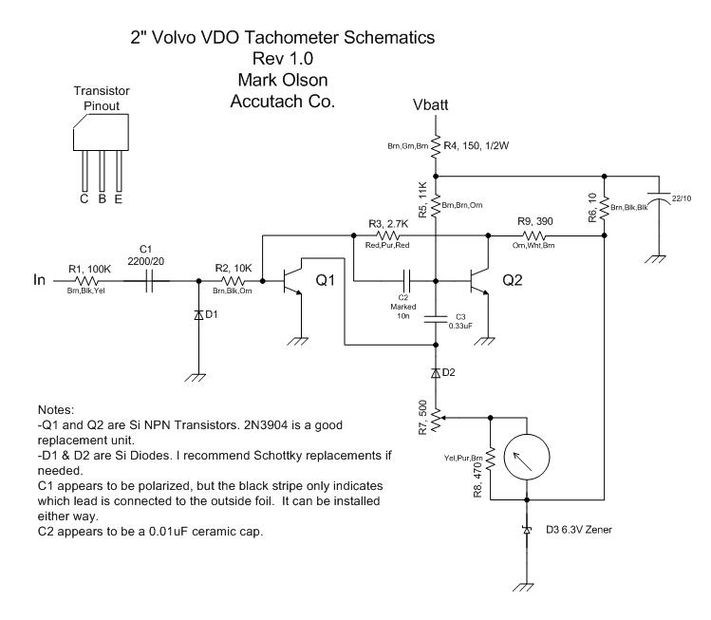

I then looked at the 2” tachometer, and the circuit was substantially the same as the 3” unit. The only differences are:

-R1 is a 100K Ohm resistor, which makes it easier to trigger the tach.

-The components in the 2” tachometer have more modern markings.

The 2” case is vertically symmetrical, so it is possible to put the tachometer innards in upside down. You should mark the 3 spade lugs per the case markings prior to taking the works out of the case.

C1 is a capacitor with a black stripe, which may look like a polarity marking, but it is not. It actually indicates which lead is connected to the outside foil, which is not important for this application. C1 in the 2” tachometer compared to C1 in the 3” tachometer, so you can’t determine the input side of the cap by the stripe.

The photo on the left shows where to attach the minigrabber test lead to C1 of the 3” tachometer and while the photo on the right shows where to attach the minigrabber test lead to C1 of the 2” tachometer:

3" Tachometer Calibration Point

2" Tachometer Calibration Point

I recommend purchasing a Minigrabber Cliplead (Pomona part # 3781-12-2) makes it easy to connect the calibration signal from the calibrator output to the input of C1.

This is a photo of the back of the 2” case. I recommend scratching the “+”, “-“ and “1” symbols into the plastic base of each corresponding spade lug to prevent upside down reassembly.

I tested the 2” tachometer and it worked, so I had no need to dismantle it. It was very close to perfect calibration, so I did not even need to calibrate it.

Finally, here is the schematic diagram for the 2” tachometer:

I hope that this analysis helps you to understand, diagnose, repair, modify and/or calibrate your vintage VDO tachometers.

Please contact me if you have any feedback regarding this document.

1967 Saab Sonnet II Tachometer

Front View

Front View

Front View

Rear View

Front View

Front View

I attempted to repair a VDO tachometer from a 1967

Saab Sonnet II. Unfortunately, I was unable to repair it, but was able to do some reverse engineering of it. You can read the reverse engineering report, including schematics here.