Smiths Tachometers

Smiths (Jaeger) Tachometers of the 60s & 70s

Years ago, Mark reverse engineered the first generation Smiths electronic tachometer in his Sunbeam Tiger, and published the results on the internet. He also developed a calibration tool for diagnosis and calibration of those tachometers. He began repairing and calibrating them for others as well as selling his calibrator.

Smiths tachometers were used in many British cars of the 60s to early 70s. They were even used in Swedish Volvos of the same era. Mark's work on the first gen tachometers led others to send him second and third generation Smiths tachometers for reverse engineering. And the Volvo community did the same for the Gen 0.5 Smiths and later optional German-made VDO tachometers for Volvos.

A great resource for a lot of information on Smiths tachometers is Alex Miller's "A Gentleman's Guide to Smiths Tachometers, V4.1".

Services

As vintage tachometers age, their permanent magnets weaken and the components age, so none of the original Gen 1 Smiths tachometers are accurate unless they have been recently recalibrated.

If your vintage car's electronic tachometer has not been calibrated recently, the chances are the aging components inside have caused the tachometer to fall out of calibration or to fail completely. AccuTach Co. can repair and calibrate most vintage Smiths & VDO electronic tachometers.

AccuTach Co. does not repair or calibrate mechanical tachometers or speedometers.

Contact us to discuss the service you need.

Products

Calibration Tool

If you are interested in purchasing a calibration tool that will empower you to debug and calibrate electronic tachometers and speedometers of a number of styles, click here.

TechnoVersions TachMatch

TechnoVersions sells a device that can allow your stock Smiths tachometer to work in cars with engine swaps or cars with modern ignition systems. We do not sell this product, but we do refer you to TechnoVersions if you need such a product. Check it out here: TechnoVersions TachMatch

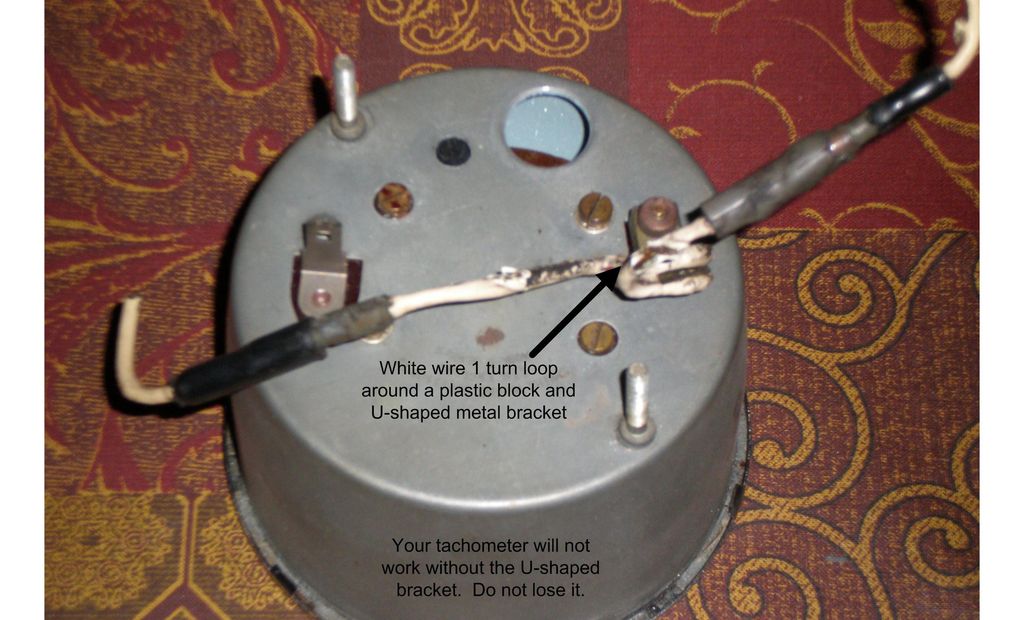

Gen 1 Smiths Tachometer Replacement Wire Loop Block and Core Clip

If you have lost the little plastic block or the little U-shaped metal clip that holds the wire loop that attaches to the back of your Gen 1 Smiths tachometer, AccuTach Co. has manufactured replacements. If you need a replacement block or core clip, click here.

FYI, the stud & nut are 6BA thread. (BA stands for British Association). They are NOT #4-40. Do not lose the nut from your tachometer.

Smiths Tachometer Background Information

Interesting Vintage Tachometer Background Information

The Smiths and VDO tachometers of the 1960s and 70s used a D'Asonval style ammeter as the needle movement. They consist of an electromagnet winding energized against permanent magnets to move their needles. Thanks to Alex Miller, I now know that The lower bearing in these meter assemblies is a hardened steel “thrust” plate and a brass bush. The upper bearing is a close fitting hole in a brass plate. I never lubricate these bearing because I have seen too many of them get gunked up resulting in binding movements. The end-play of the bearing can be adjusted if you remove the needle to expose the adjustment nut. (Alex also tells me of a 4th generation Smiths tachometer that uses plastic bearing. I have no experience with the plastic bearings in these newer tachometers.) The tachometers are driven by either a magnetic pulse or voltage pulse from the ignition, depending on the tachometer.

Generation 0 Smiths Tachometers

Gen. 0 Smiths tachometers were used in cars such as Jaguars starting in the 1950s. They consist of a head unit In the dash made of an ammeter and a bridge rectifier. The tachometer signal came from an alternator connected to a camshaft. The alternator generated and AC signal that increased in frequency and amplitude with increasing RPM.

Generation 0.5 Smiths Tachometers

Gen. 0.5 Smiths tachometers were used in Jensen assembled Volvo P1800s starting in 1960 through part of 1964. They consist of a head unit in the dash and a potted electronics module in front of the radiator. The head unit was made of an ammeter and a wire-wound resistor. The tachometer signal came from the negative side of the coil and went the the electronics module. The module then controlled the amount of current going through the head unit's meter.

I was fortunate enough to get my hands on one of the Gen 0.5 potted electronics modules and was able to reverse engineer it with the help of Alex Miller. The modules cannot be repaired, but if you are interested in how they were designed and how they work, you can read our document about it here.

Details of the Smiths 1960s Style RVI Inductively Coupled Generation 1 Tachometers

The older Smiths tachometer must be disassembled in order to calibrate or repair it. Carefully rotate the chrome bezel until the tabs on the bezel line up with the slots on the case. This can be a very difficult job if the seals have aged badly and stuck. Whatever you do, DON’T pry up the tabs on the bezel or you’ll ruin it. We use a pair of plastic strap wrenches with rubber straps to rotate the tough bezels. Don’t tap the bezel edge as the meter is very fragile.

Early Volvo P1800s have a large chrome bezel that is crimped to the case. It needs to be carefully uncrimped if you need access to the inside of the tachometer. Later P1800s have a black bezel that is the same as the chrome bezel described above.

Once you get the bezel off the tachometer, the face glass and inside bezel must come out, if they didn’t come out with the chrome bezel. Carefully pry the inner bezel from the case. It is not necessary to separate the glass from either bezel if it is stuck to one of them. Be careful prying on anything, especially if the glass is still in place, as it is very easy to damage it or the bezels. I have not been able to locate a source for the seals, so I just try to be very careful, and reuse what I can with what’s left of the seals. I always use a lint free cloth and glass cleaner to clean the glass while the tachometer is apart.

Once the meter face is exposed, be very careful not to mar or get finger prints on the face or break the needle. The next step is to remove the tachometer innards from the case. There are four screws on the back of the case, two of which are recessed in holes in the case and two of which are not. The two in the recessed holes hold the innards of the tachometer together so don’t take them out. Put the tachometer case face down on the bench. While pinching the “U” bracket stud with one finger and the power spade lug with another to hold up the tachometer innards, remove both of the non-recessed screws. The tachometer innards are now being held in the case by your two fingers. Pick up the case and cup your other hand under the face of the case. Carefully let the stud and spade lug slide out of your fingers and catch the face of the tachometer by the edges in the cup of your hand. You can then pull the case off of the tachometer innards and turn it over. You are now ready to calibrate or debug the tachometer.

This is a good time to slide a shield under the needle to shield the face and repaint the needle if you can find appropriate paint. (My artistic talents aren’t very good, so I never try that step myself.)

Here are the schematics of the Generation 1 Smiths Tachometer:

Generation 1 Smiths Tachometer Schematics

Thanks to Tom Hayden, we know that the Vishay BC NTCLE100E3331JB0 (Digikey BC2418-ND) is a good replacement for the thermistor in Gen 1 tachometers.

Electronically, the Gen. 1 Smiths tachometer is a relatively simple two Germanium transistor inductively coupled electronic tachometer.

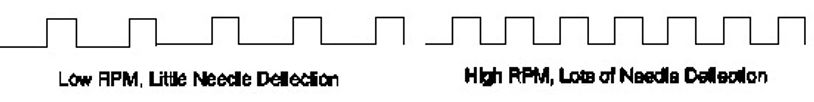

The two transistors together form a monostable multivibrator, or one-shot. Normally, the collector of Q1 is at 6V. An ignition pulse couples through the transformer to trigger a one-shot voltage pulse to 12V on the collector of Q1 for a set amount of time. Every time an ignition pulse is detected through the transformer, the collector of Q1 will pulse from 6V to 12V for a fixed amount of time. While the collector of Q1 is at 12V, the top of the meter is held at 6V by the Zener diode, so current will flow through the meter, causing the needle to deflect. The width of the voltage pulse is determined by the combination of the 0.25uF capacitor C2 and the combination of resistors R3, R5 and pot R4. The one-shot is triggered by every ignition pulse, so the voltage waveform looks like a series of pulses when the engine is running. Since the pulses are fixed in width and the frequency of the pulses is determined by the engine speed, the ratio of the time the waveform is at 12V vs. 6V goes up with increases in engine speed and down with decreases in engine speed. The way the meter works, the more time the waveform is at 12V, the more the needle is deflected and the less time the waveform is at 12V, the less the needle is deflected.

NeedleDeflection

To calibrate the meter, you want to drive the tachometer with a very accurate, known signal at the correct frequency for the RPM reading that you want on the meter. Once you are driving the tachometer with the accurate frequency, you can adjust the needle deflection to the proper place by turning the calibration pot. R5. The tachometer can only be calibrated at one RPM. After that, all you can do is check to see how close you are at other RPMs.

It is possible to recalibrate the 7,000RPM Alpine 4 cylinder tachometers to work in V8 Tigers using this method.

The most common failure modes I have seen are failure of the main timing capacitor C2. Failure of this cap. has caused tachometers to be erratic, temperature sensitive or just plain dead. If you suspect your tachometer to have this problem, locate the capacitor, carefully unsolder the capacitor, and replace it with a new one. I have not been able to locate a supply of 0.25uF capacitors, but available 0.22uF to 0.27uF capacitors work fine. I have yet to come across a tachometer with a failed transistor, but they are rumored to cause problems as well. The other major failure mechanism I have seen is a broken meter spring. The meter needs to be replaced in this case. Replacement meters must be gotten from a parts tachometer. As a matter of course, the tachometer will have to be recalibrated if any of the parts are replaced.

All of the Smiths tachometers of this era use the same electronic and mechanical design, regardless of number of cylinders, positive or negative ground or the make of the car. The power and ground wires are reversed between tachometers for positive or negative ground cars. The only other thing that changes is the face used on the meters. So don’t throw away any vintage Smiths tachometers or tachometer parts. They can be used to resurrect any other one.

Trevor Goodenough of the UK developed a clever method to reverse the polarity of this tachometer for his Aston Martin. He reversed the polarity of the Zener Diode, main timing cap (replacing it with a new one in the process) and the meter movement wires. Then he replaced the germanium PNP transistors with Mullard AC127 germanium NPN transistors (NTE103A is an equivalent.) His tachometer is working perfectly in his Aston Martin that was converted to negative ground.

Here are the 3 Youtube videos he published regarding his conversion:

You can identify a Gen 1 Smiths tachometer by the wire loop/plastic block interface on the back:

Gen 1 Smiths Tachometer

If the wire loop/plastic block is missing, you will see the stud that it screws into:

Gen 1 Smiths Tachometer

Since Gen 1 Smiths tachometers read the ignition current signal rather than a voltage signal, the tachometer input loop needs to be somewhere in the coil primary circuit. Most British cars have the loop in the wire that runs from the ignition switch to the positive side of the coil. But some cars, such as at least some Volvos, have the loop in the wire between the coil negative and the distributor points/condenser.

Gen 1 Smiths Tachometer Wiring Diagram

Gen 1 Smiths Tachometer Wiring Diagram

Details of the Late 1960s/Early 1970s Style RVI Inductively-coupled Generation 2 Tachometers

Sometime around the late 1960s, Smiths went from a two transistor tachometer design to a one transistor blocking oscillator one-shot tachometer. I was sent a tachometer from a 1972 6-cylinder Jaguar for analysis and repair. I reverse engineered the circuit, and figured out how to repair the one transistor tachometers.

This tachometer runs the ignition wire inside of the tachometer case where it is wound with 3 turns around a toriod core. The signal is coupled into the tachometer circuit via a winding with about 90 turns. One side of that winding is connected to battery voltage, and the other side is connected to a series RC network, with the capacitor also connected to battery voltage. The middle of the RC network is connected to the base of a Germanium PNP transistor marked MT59/A. The emitter is connected to battery voltage and the collector drives the meter, a 30 turn (approx.) winding on the same toroid core, and a resistor to ground. The 30 turn winding provides feedback that keeps the one shot going until the RC network times out.

There is a 50 ohm trim pot in the RC network that allows calibration of the pot by varying the one-shot pulse width.

Note that the electrolytic capacitor polarity is upside down from what you might expect. The reason for that is that the emitter-base junction of the transistor prevents the base of the transistor from going below about 0.5V less than battery voltage. But the voltage on the base can go well above battery voltage as it couples through the transformer. Be careful not to reverse the polarity of the capacitor when replacing it.

I learned that the NTE176 is a good replacement transistor for repairing these tachometers. Here is the schematics I have drawn for this circuit.

I have also learned while repairing a 70 Volvo P1800 tachometer that, if corrosion occurs at the point where the calibration pot contact presses against the PCB trace, the tachometer will work intermittantly or fail completely. I recommend lossening the calibration pot nut, spraying the area there the pot contacts the PCB under the pot with a good electrical contact cleaner and then retightening the nut to ensure the pot makes good contact with the PCB. the tachometer will start working again if that is the problem.

I have measured a Gen 2 tachometer thermistor that looks to be in very good condition at exactly 25 degrees C and measured 10.6 Ohms. I was able to find several 10 Ohm NTC through-hole thermistors from a number of on-line electronics distributors. If you need to replace a thermistor, any of those will probably work.

You can identify a Gen 2 Smiths tachometer by the male and female bullet connectors on the back of the tachometer case:

Gen 2 Smiths Tachometer

Details of the 1970s Style Direct-coupled Gen 3 Tachometers

he newer style Smiths tachometers such as those found in the 1971-1975 Series-3, E-type V12 Jaguars do not need to be disassembled to calibrate as long as the case has a hole that exposes the calibration pot (as the sample unit I have does.)

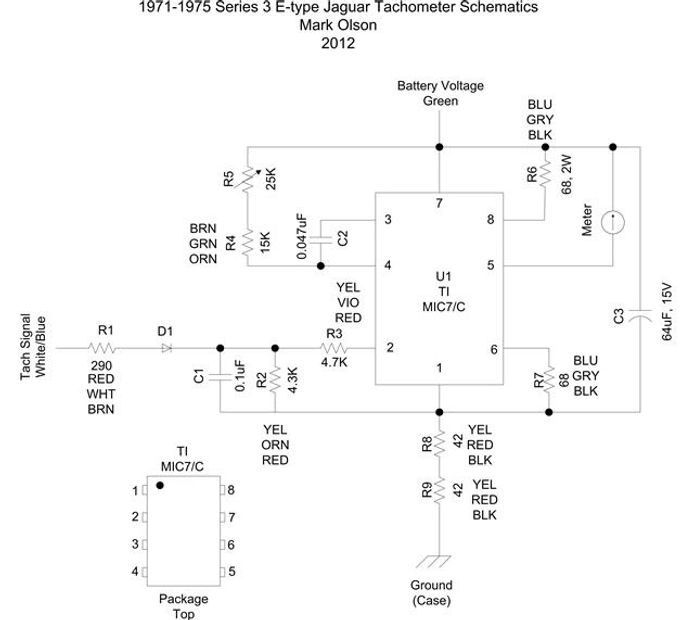

The newer style Smiths tachometers use the same one-shot architecture that the older style uses, but it was implemented in a custom version of the Texas Instruments SN7610 integrated circuit (called "MIC2/C), rather than with all discrete components as the older tachometers were. Note that my drawing below indicates that the IC is labeled MIC7/C. This came from reading an IC with a damaged "2" mark when I drew the schematics. There are a few discrete components around the IC. The newer design is much more robust and reliable than the older designs, but may still require recalibration as they age.

Here are the schematics of the Gen. 3 Smiths Tachometer:

1970s Gen 3 Smiths Tachometer Schematics

I have found it to be challenging to diagnose some Gen 3 and Gen 4 tachometer failures, beyond checking the meter movement for broken springs. I have proven that an IC called the SAK 215 is a pin compatible part that may work as a replacement IC for this generation of tachometer. There is a difference between the TI SN7610 and the SAK 215. The pulse width spec for the SN7610 = 0.7*R*C and for the SAK 215 it is 0.64*R*C. If the SN7610 is replaced by the SAK 215 in a tachometer with a calibration pot, the calibration may be able to compensate for the differences in time constants, but components will need to be changed in tachometers without calibration pots. Please contact AccuTach Co. if you want to try substituting an SAK 215 for a SN7610 in a tachometer without a calibration pot. I have learned that, if a Gen 3 or Gen 4 Smiths tachometer fails in a mode where it slams the needle to the peg when it is powered up, replacing the IC can bring it back to life.

I now have the SAK215 ICs in stock and can repair Gen 3 or 4 tachometers if the IC fails. If you have other problems, please contact us to see if we can help.

You can identify some Gen 3 Smiths tachometers by the two wires coming out of the back of the tachometer case. They are terminated with a bullet connector with a male and female pin on each wire:

Gen 3 Smiths Tachometer

Special thanks to Dick Wells for his Jaguar tachometer loan as well as a lot of good Jaguar information.

Some Gen 3 Smiths tachometers have a single male bullet connector for the tachometer input signal and a single male spade connector for power. They typically have a calibration hole that was covered by a calibration seal.

Gen. 4 Smiths Tachometer

The Gen. 4 tachometers look very similar to the Gen 3 tachometers with a male bullet signal connector and a male spade power, usually with no calibration hole. The main difference is inside. The circuit used in the Gen 4 tachometers is very similar to that of the Gen 3 tachometers including the use of the TI MIC2/C integrated circuit. But the printed circuit board used in the Gen 4 tachometers is very different from the Gen. 3 PCBs. The components on the Gen 4 PCB are surface mounted and all of the resistors are thin film resistors embedded in the PCBs.

For a lot more information on Gen 4 Smiths tachometers, please download Alex Miller's Gen. 4 Smiths Tachometer document here.